From Reactive to Proactive: Building a Culture of Safety Verification in Traffic Management

In traffic management, mistakes can be costly—not just financially, but in terms of safety, trust, and future business. Too often, contractors find themselves reacting to problems: an inspector flags a non-compliant setup, a motorist lodges a complaint, or worse, an accident occurs. At that point, the damage—financial, legal, and reputational—has already been done.

But what if the industry flipped the script? Instead of firefighting after incidents, contractors could build a culture of proactive safety verification—where compliance and evidence are embedded into daily workflows. This approach not only reduces risk but also builds trust with clients and regulators, creating a competitive advantage.

1. The Problem with Reactive Compliance

Most traffic management contractors already have processes in place: TMPs are prepared, daily diaries are completed, and supervisors conduct inspections. Yet too often, these systems are treated as paper exercises—something to be filled out and filed away, rather than living safeguards.

When things go wrong, the industry tends to react:

Audits uncover errors in signage or placement.

Complaints arise from residents or motorists.

Incidents occur, triggering investigations or even litigation.

In each case, the contractor scrambles to explain, justify, or defend themselves. This reactive posture is costly and stressful—and increasingly unsustainable as regulators tighten requirements.

2. Why Proactivity Matters More Than Ever

Across Australia, regulators are raising the bar on compliance.

In Western Australia, from 1 January 2025, Main Roads WA requires contractors to retain site compliance evidence, including drive-through video recordings, under the updated Code of Practice for Traffic Management for Works on Roads (MRWA, 2025).

In Victoria, the Department of Transport and Planning’s Traffic Management Surveillance Framework (2023) introduced random and risk-based inspections, meaning any site can be checked at any time.

In Queensland, updates to the Manual of Uniform Traffic Control Devices (MUTCD) place emphasis not only on TMP design but also on execution and verification on-site (DTMR QLD, 2023).

The message is clear: regulators are no longer satisfied with paperwork—they expect evidence of what happened on the ground. Contractors who only react after breaches are putting themselves in jeopardy.

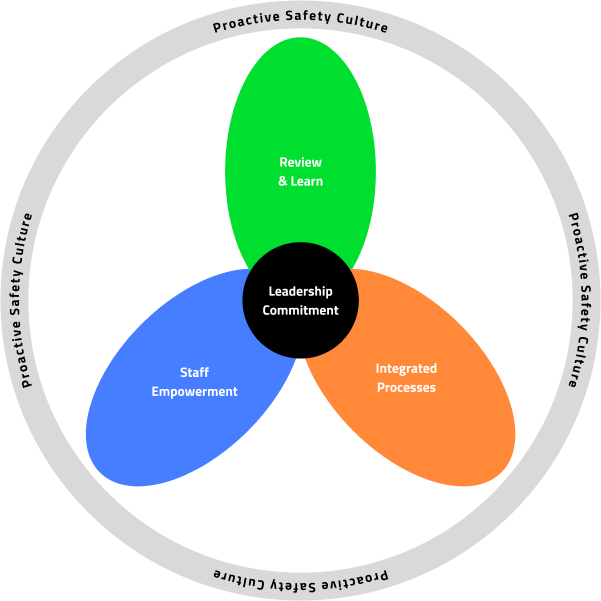

3. What Does a Proactive Safety Culture Look Like?

Proactivity is more than compliance—it’s a mindset shift. It means embedding safety verification into every step of project delivery.

Key elements include:

a) Leadership Commitment

Culture starts at the top. Company directors and managers must demonstrate that safety and compliance are non-negotiable values, not just checkboxes. Research shows that organisations with strong safety leadership see fewer incidents and higher employee engagement (Safe Work Australia, 2021).

b) Crew Empowerment

Frontline staff need to feel empowered to flag issues, record setups, and speak up without fear of reprisal. Training should stress that verification is part of the job, not an optional add-on.

c) Integrated Verification

Verification should not be a separate burden but an integrated process:

Quick drive-through recordings after setup

Daily checklists linked to photos/videos

Simple, consistent routines that become second nature

d) Learning from Near Misses

A proactive culture treats near misses as learning opportunities. Capturing and reviewing incidents—even small ones—prevents bigger failures later.

4. Benefits of Proactive Verification

Shifting from reactive to proactive has tangible payoffs:

Fewer Fines and Penalties – By ensuring compliance before inspectors arrive, contractors avoid costly regulatory action.

Stronger Client Relationships – Councils, utilities, and road authorities increasingly demand transparency. Contractors who provide evidence proactively inspire confidence.

Reduced Legal Risk – Video and photographic evidence serve as a defence in the event of litigation, proving due diligence.

Operational Efficiency – With clear records, disputes are resolved faster, crews spend less time redoing work, and projects flow more smoothly.

Improved Reputation – Contractors who consistently demonstrate compliance build a reputation as reliable, professional partners.

5. Real-World Examples

Example 1: Western Australia

A Perth-based contractor adopted routine drive-through recordings for all projects in late 2024. When MRWA’s new rules came into force in 2025, the company was already compliant. During a random audit in March 2025, they produced timestamped recordings showing perfect alignment with their TGS. Result: no fines, no delays, and positive recognition from the regulator.

(Source: Main Roads WA, 2025 update on compliance requirements)

Example 2: New South Wales

In 2023, SafeWork NSW fined multiple contractors for unsafe site setups, including inadequate signage and poor barrier placement, totalling more than $55,000 in penalties (SafeWork NSW, 2023). Contractors without proper verification records struggled to contest the findings. Those with visual evidence of their setups, however, successfully defended against some allegations.

(Source: SafeWork NSW Annual Report, 2023)

6. How to Build a Proactive Verification System

Transitioning from reactive to proactive requires deliberate steps:

Audit Current Practices

Are TMPs/TGSs updated regularly?

Are daily diaries backed by evidence?

How is compliance currently verified?

Introduce Visual Verification

Require short, timestamped drive-through videos post-setup.

Link them directly to TMPs/TGSs.

Digitise Record-Keeping

Use cloud platforms to store evidence for at least 7 years.

Ensure records are easy to retrieve during audits or disputes.

Train and Engage Crews

Provide training on why verification matters.

Show crews how it protects them personally from liability.

Review and Learn

Hold regular reviews of verification records.

Use insights to improve future site setups.

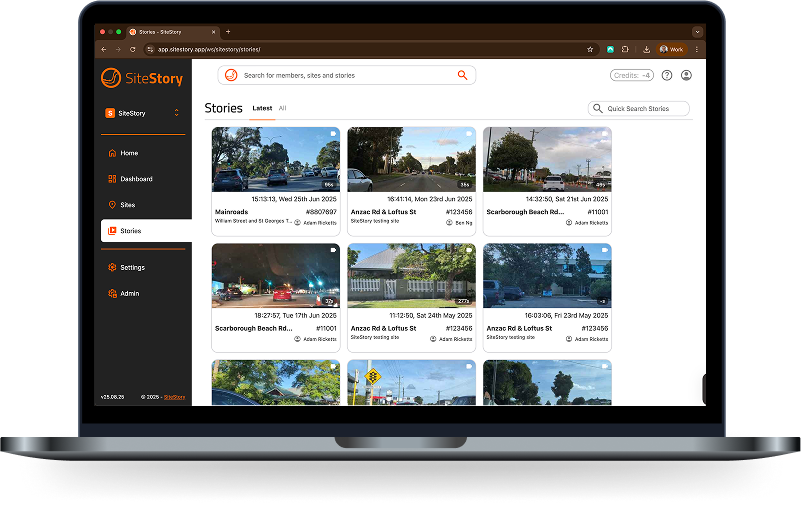

7. Subtle Role of Tools Like SiteStory

While this isn’t about selling a specific product, solutions like SiteStory embody the principles of proactive verification:

A purpose built tool for video evidence to record all job site types and monitor compliance.

Automatic timestamping and geo-tagging ensure accuracy.

Integration with job systems mean immediate linkage to jobs for quick retrieval and cataloguing, whilst referencing the correct setup.

7-year retention guarantees evidence is available long after project completion.

The key is not which system is used—but that contractors move beyond paper records and embrace modern, verifiable compliance tools.

Conclusion

Reactive compliance leaves contractors exposed to fines, delays, litigation, and reputational harm. By contrast, a proactive safety verification culture turns compliance into an asset: reducing risk, building client trust, and protecting workers and the public.

With regulators across Australia tightening requirements and demanding evidence, the choice is clear. The future belongs to contractors who prove compliance before problems arise.

References

Main Roads WA. (2025). Code of Practice: Traffic Management for Works on Roads (updated 1 January 2025).

Department of Transport and Planning Victoria. (2023). Traffic Management Surveillance Framework. Victorian Government.

Department of Transport and Main Roads Queensland. (2023). Manual of Uniform Traffic Control Devices (MUTCD), Part 3: Works on Roads.

SafeWork NSW. (2023). Annual Report 2023: Construction and Traffic Management Compliance.

Safe Work Australia. (2021). Work Health and Safety Leadership and Culture Report. Safe Work Australia Publications.